0 Introduction In the early 1980s Chinese government made a decision to improve Chinese welding training system. Through evaluation and comparison on the training systems in different countries, it came to a conclusion that German system might be a good choice. After connecting with German Welding Society (DVS) located in Dusseldolf, it was determined that German training experts were invited to the importance industry city in the north of China-Harbin and introduced DVS training system. In the cold deep autumn of 1984, four welding instructors from Duisburg Welding Training Institute (Duisburg SLV) of Germany came to Harbin with the purpose on showing the capability and level. Because both parties felt satisfied with the trial cooperation in the early stage, State Economic and Trade Commission of P.R. China (SETC) and German Economic and Technical Cooperation Ministry (BMZ) made negotiation about the cooperation programmes, which was executed by The Ministry of Mechanical and Electronic Industry of P.R. China (MMEI) and German Technical Cooperation Company (GTZ).

The technical service of this aid programme was undertaken by SLV Duisburg which was responsible to implement this programme in detail. The Sino-German cooperation programme was carried out in three stages including the first, second and third term and the support term.

During the period of the Sino-German cooperation (1987-1999), there were total 32 Chinese technical persons dispatched to Germany to receive the training and all of them were awarded the professional diplomas such as European Welding Engineer (EWE), which trained teaching faculty and translators for future Sino-German cooperative courses. German partner assigned Dr.-Ing Karl Million (1987~1992) and Dip-Ing Einick (1992~1997) as long term programme experts and several batches of short term experts. Both Chinese and German teachers and the examiners authorised by DVS went to the areas , oilfields and large enterprises such as Beijing, Shanghai, Suzhou, Daqing, to organize courses and examinations of EWE, European Welding Specialist (EWS), European Welding Inspector (EWI), European advanced Non-destructive Testing Personnel, Welding Instructor and Welders, serving for large projects and enterprises such as Shan-Jing Pipe-line Installation Project, Daqing Oilfield Construction, electrical equipment fabrication companies in Harbin, Shanghai and Sichuan areas. We also trained many leading welding technicians with international qualification and lots of welders with international certificates for foreign capital companies and export-oriented enterprises. Both parties trained and qualified 178 EWE, 125 EWS, 108 EWI, 836 German DVS Instructors, over 5000 European and German welders (totally more than 15000 welders got trained according to various kinds of standards), 108 International Welding Engineers (IWE) through transition arrangements from EWE, over 100 candidates in special courses such as Welding Structure Designers, 29 European ultrasonic testing personnel at Level III, 48 European ultrasonic testing personnel at Level II.

In order to fully introduce German welding training system to China, over ten kinds of training materials and European/German standards with more than million characters in German were translated into Chinese for training, and German guidelines and teaching methodology was also introduced into China during the implementation of the programme. Meanwhile, the course delivery was transferred from German experts to Chinese teachers step by step and finally Chinese teachers finished the training course themselves, which made a sound basis for the international harmonization scheme of Chinese welding training and qualification later.

There were two significant classes which were once held first time in the world in the Sino-German cooperation programme: EWI class held in Harbin in March 1996 through Sino-German cooperation, in which 31 candidates were awarded the diplomas; and the other is the first qualification transition class from EWE to IWE held in Harbin in 1999 also through Sino-German cooperation, in which 108 persons got IWE diplomas.

1 CANB authorized by IIW a successful sign of Sino-German cooperation

The satisfying achievements from the first, second and third terms of Sino-German cooperation made Chinese and German government full confidence of programme introduction so that both parties decided to add a supporting term with two years. The aim was to make Chinese welding training and qualification system and organisation pass the assessment of International Institute of Welding (IIW) by the end of 1999 when the programme ended. Therefore CANB was founded in Harbin in 1998 and the first CANB council meeting was held in which CANB constitution was approved and the structure such as the governing board was created by voting. In spring 1999, Mr Ahrens (the chairman of IIW commission VII of the time) from SLV Duisburg came to Harbin and made consulting review of application documentation in English version which CANB would submit to IIW. CANB then submitted the amended application documentation to IIW for paper assessment. The printed application materials were approved by IIW assessors and the on-site audit was arranged as 7-9 September 1999 in WTI Harbin of China.

WTI Harbin had made a series preparation for assessment. Mr Yu Zhenping, CANB Chief Executive at the moment was assigned to Europe to learn about experience and attend IIW training and qualification meetings. Professor Wu Lin, the former president of Chinese Welding Society and a member of IIW Board of Directors of the time, and Mr Zhang Yanmin, the vice chairman of CANB Governing Board, came to WTI Harbin to direct the preparation work for assessment. Mr Lu Yansun, the former vice minister of the Mechanical Industry and the president of Chinese Welding Association by the time, Mr Song Tianhu, the chairman of CANB Governing Board and Secretary General of Chinese Mechanical Engineering Society, Prof. Pan Jiluan and Prof. Lin Shangyang, members of Chinese Science Academy, also came to Harbin to instruct the on-site assessment work.. (see Fig. 1)

Fig. 1 The leaders from Chinese welding industry and WTI Harbin during on-site assessment

Mr Timothy James Jessop, IIW Leader Assessor from TWI of the UK , and Professor Wolf-Dieter Strippelmann, IIW Peer Assessor from Manhime Welding Training Institute of Germany, came to Harbin to conduct on-site audit. In the first two days (7-8 September 1999), they focused on CANB quality management documents, file management, examination Q&A bank, organization structure, and the first Approved Training Body(ATB). On the third day (9 September 1999), they visited the first ATB, WTI Harbin. During the time the leaders and experts from Chinese welding field interviewed with the IIW assessors and made discussion and exchange. In addition, the government also paid great attention to the cooperation programme and international assessment. Wang Zongzhang, Wang Huafang, Fang Cunzhong, Yue Yuquan, the leaders of Heilongjiang Province and Harbin City interviewed IIW experts and introduced the development of welding and allied industries in Harbin , expressing the support of the government to the international assessment on CANB and WTI Harbin (see Fig. 2).

Fig. 2 The leaders of local government interviewed IIW Assessors

The IIW assessors were deeply impressed by the great attention and support from government and welding industry. As they said when interviewed with the journalist of Harbin Daily ?ê? ???Through paper assessment, talk with technical staff and observation of hard work of Chinese welding persons, China will be the first country which has ever made complete application and been accepted outside Europe. The Chinese welding personnel who are awarded IIW diplomas will be recognized in the world.

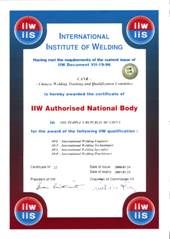

The two assessors made positive remarks and full affirmation on the work of CANB and WTI Harbin at the exit interview meeting. Their assessment report was approved at the meeting of IIW Authorisation meeting by voting in Paris in January 2000 so CANB got full IIW Authorisation. Many media and newspapers of China made reported in time and gave high remarks on this event and among them, Harbin Daily issued a top piece of news with the title. The IIW authorisation certificate was signed jointly by IIW president and the chairman of IIW Authorisation Board with five years of validity (see Fig. 3). The four authorised categories were all the courses that IIW implemented in the world at the moment: IWE, International Welding Technologist (IWT), International Welding Specialist (IWS), and International Welding Practitioner (IWP).

Fig. 3 The IIW authorisation Certificate

2 Excellent achievements brought by international authorisation within five years

It's a real proud of Chinese welding industry being the first country authorized by IIW outside Europe . A t the same time it cared about how Chinese welding training and qualification system would develop at healthy and fast pace after Authorisation. When five years' re-assessment was coming, CANB and WTI Harbin made the whole welding industry and German copartner feel proud of the excellent achievements that the number of accumulated awarded diplomas ranked the second in the world ( Germany ranked the first) according to IIW IAB statistics in the annual report of 2004. The trained and qualified welding technical personnel came from various industry fields such as machine, metallurgy, electric power, transportation, petrochemical etc. More than 50 classes were held in many places within the short time of 5 years, and near 2,000 welding persons at various levels including IWE were trained and qualified, mainly benefited from wide participation of many local welding societies and associations, intensive cooperation with universities, companies and training institutions as well as the high attention and support. Among the training classes, over 50 per cent were organized together with local welding societies and associations, which offered convenience for more technical personnel to study convenient international welding technique knowledge and standards and obtain international qualification more at the same time, and increased the budget and activity contents for local societies and associations. The cooperation with universities even more meet the requirements of university reform, as news media reported about theIWE courses held jointly by WTI Harbin and Harbin Institute of Technology(HIT). In September 2000, in order to enhance the comprehensive quality of the graduates, the Welding Department of HIT made discussion with the first IIW authorised WTI Harbin in China, both parties decided to hold IWE courses through combination of the graduate teaching plan of welding major of HIT with IIW IWE guideline. The graduates who take part in the classes and pass the examination successfully can be awarded IWE diplomas recognized in the world, making the graduates more competitive in finding jobs. There have been over ten universities holding courses with WTI Harbin one after another.

Since China has joined WTO and emerged into international market, that enterprises demand a large number of welding technical persons with international qualification so as to strengthen their force in market competition is the main power to drive the development of welding training and international qualification business. For instance, A large port machinery company in Shanghai which shares about 50% of the world market value sent over ten leading technical persons including their vice chief engineer successively to attend IWE courses. To pass the certification of DIN18800 steel structure, they had nearly 400 welders trained and tested at one time according to EN287( ISO9606) . A famous Chinese railway enterprise once held a special IWE class for its own welding technicians in order to make cooperation with global famous SIMENS Company.

Many domestic and foreign capital companies have also trained and qualified a lot of welding professional persons with international qualification and/or certification to increase their competition capability in the international market.

The work of WTI Harbin has also won the high attention and recognition of local government. The government of Harbin City issued a document to implement the reform on the approval system of professional title of welding engineers in the city, which has begun since 2002. That is, the approval mechanism is replaced by means of IWE examination instead of panel evaluation and review. At the same time, it recognized the validity of IWE diplomas in the profession title approval. Thus the recognition of IWE qualification was realized by the local government in China .

3 The extension and development of Sino-German cooperation

When the cooperation programme between Chinese and German government was completed at the end of 1999, WTI Harbin and German SLV Duisburg signed a continual cooperation agreement. Both parties would continue to make cooperation in the training fields such as EN287( ISO9606), what is more, they would expand their cooperation scope and focus on international company certification, consultation and inspection for quality assurance of welding fabrication.

Through the joint effort of both parties, over ten companies can be consulted and jointly certified every year, and the certification categories have covered: EN729/ISO3834, DIN18800, DIN6700. The cooperation has not only made German party to be more well-known and expand their market in the field of company certification in China , but has helped China train the profession persons of company certification and consultation as well. The most important is that it has offered important experience for China to set up its own welding fabrication company certification and to realize international harmonization.

At present, WTI Harbin has obtained the programme fund support from the related departments of Chinese government for the scheme of international harmonization of company certification of welding fabrication and has achieved good results phase by phase. Sino-German training and qualification of welding personnel has provided us with successful experience, the international harmonization of Chinese national welding standards has been made progress continuously, and the integration of global economy is getting faster, which call for the international harmonization of welding fabrication company certification.

4 Development of welding training, qualification and certification

Wide alliance and joint effort promote the accelerated development of Chinese welding training and international qualification and certification. The achievements that China has made in welding training and qualification were thought highly of by IIW. CANB and WTI Harbin have successfully passed the intermediate surveillance in 2001 and the first re-assessment in November 2004 by IIW appointed assessors. The authorised course categories have been extended to have International Welding Inspection Personnel and International Welder.

The re-assessment and extension of scope must be able to promote the development of Chinese welding training and qualification, especially the training of International Welder and the welder certification according to ISO9606 will attract more training bodies to join the system as it happened in some industry countries. CANB is actively getting ready to offer information and consultation service to applicant organisations and WTI Harbin will also provide help and support with its years of experience actively.

In order to offer more opportunities for Chinese welding industry, WTI Harbin is actively developing distance learning programme and trying to realize the leap development of welding training and international qualification as well as certification by adopting information technology and digital video-audio techniques. |